Plant and special machine construction

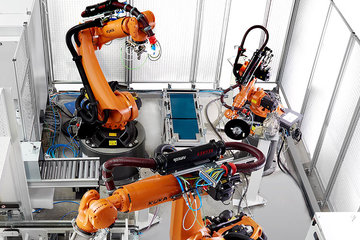

Based on standardized concepts, HEITEC supplies you with customer-specific machines and systems to solve your tasks. This reduces costs and increases reliability. Over 40 years of experience in plant engineering, mechanical engineering and robotics guarantee you high flexibility, availability and productivity of your production system. With over 300 turnkey systems installed worldwide, we are your competent partner for automating your processes.

Products ans solutions

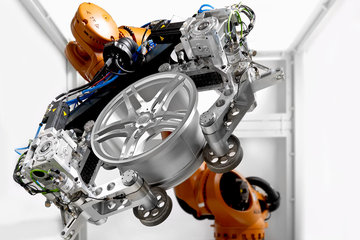

- Automation and robotics

- Assembly systems

- Machining centers

- Measurement and test engineering

- Industrial X-ray technology

Digital engineering

Software-based support for engineering processes through virtual models of machines, systems, robot applications and material flows is a key productivity lever in plant construction. In this way, automation concepts are tested both in terms of their functionality and their time behaviour and process sequences are optimised even before they are implemented.

HEITEC 4.0 uses real commissioning on the virtual model to map all current and future operating processes in the corresponding production environment in real time and controls them with the original automation software. In this way, a higher delivery quality of the software for automation and drive solutions is achieved and design and process errors are recognised at an early stage. Parallelisation of the development processes significantly minimises the project duration. By extending the virtual system to the logistics area, material flows are simulated and the system software is adapted to the real system layout and workflows. This facilitates commissioning and the testing of alternative solutions.

Services & support

The high availability of our systems cannot be guaranteed by high-quality components and well thought-out processes and solutions alone. Timely replacement of wearing parts and competent and fast service are just as important.

For this reason, we offer our customers maintenance contracts. An integrated counter can also indicate how many parts have been produced and when a component needs to be replaced. In many cases, we can help with problems via remote maintenance - quickly and cost-effectively.

Our employees have years of experience and have accompanied your system from development to installation and commissioning. We are also happy to assist you with professional maintenance or troubleshooting.

Our services

- Robot programming

- Virtual engineering

- PLC programming

- NC programming

- Function and safety acceptance tests

- Motion and material flow simulation

- System optimisation

- Safe acceptance tests

- Qualification/validation

Software development

HEITEC offers you innovative solutions for newly planned projects as well as for plant modernisation (retrofit, reuse), from planning expertise to integrated automation in plant and mechanical engineering.

A qualified team of automation engineers and technicians (electrical engineering, IT, mechatronics) is at your disposal for your tasks. In addition to the broad-based expertise, flexibility and dynamism in project management are particularly important characteristics that ensure project success.

We can provide the following services in full or in part:

- Consultancy, planning and design

- Engineers with experience as project managers and specialists

- Software development and application, e.g. in the areas of MES, process control technology, database applications, ERP and interfaces

- Control and drive technology, etc. PLC programming, drive solutions Motion, NC

- Visualisation, e.g. with HMI/SCADA

- Robot programming (ABB, adept, KUKA, Stäubli)