Digitalization

At HEITEC, digitalization is a fundamental component of our strategy and is a function that spans across all our business areas. After 15 years of accumulating in-depth experience and knowledge in the fields of digital engineering and smart factory, we are constantly expanding our range of digitalization solutions. We not only focus on the development of new technologies, but also exploit the potential of existing, modern technologies for maximum efficiency.

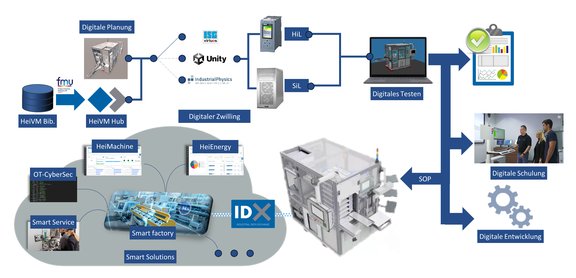

Our portfolio along the product lifecycle

Our solutions in digitalization

Why HEITEC?

-

50 years of industry expertise

-

Our highly specialized library

-

Use of the latest technologies

-

From conceptual design to 24/7 service

Digitalization at HEITEC means incorporating the requirements of our users right from the development stage, offering a solution that offers maximum user-friendliness and usability. After all, the digital transformation can only be successfully implemented if digitalization is also practical in everyday life.

Digitalization success stories

Virtual commissioning - system expansion during ongoing production

Real plant expansion in the automotive industry during ongoing production within 3 days, through effective design and fast assembly on customer site by Kiener Maschinenbau with the support of virtual commissioning by HEITEC.

Optimization of cycle times with the help of the digital twin

A leading international company in the fields of variable camshaft phasers and transmission valves has commissioned HEITEC to virtually commission an existing plant to identify potentials with the help of the digital twin due to a cycle time optimization measure and thus initiate targeted retrofit measures.

More quality in production through transparency

Buchner GmbH & Co. KG is a company that specializes in the production of complex plastic trays using a thermoforming process and is active in a wide range of metal processing applications. The aim was to detect anomalies in the movement of a system and to monitor temperatures.