Automatica 2018: Planning faster, producing faster

01.06.2018

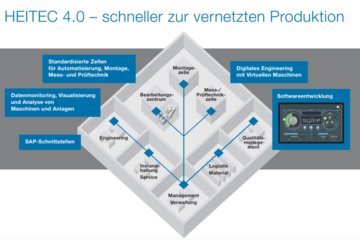

Graphic: Heitec 4.0 gets you into networked production faster (source: Heitec)

Automation and digitalization are defining factors for a production system that looks to the future. That’s especially the case when planning, engineering and commissioning procedures are supported throughout by software-based virtual models of machines and systems. Erlangen automation specialist Heitec is developing a digital twin for the purpose, as a companion for the real equipment.

Heitec can draw on a considerable store of object-oriented technology objects as a library for digitalizing machines and systems. The right virtual models make it possible to detect errors in planning, design and software early, and can reduce project completion times by about 20 percent and on-site commissioning times by up to 80 percent. Building on the concept of virtual plant design, with HeiVM Heitec has developed a dynamic model of a plant, complete with all communication, sensing and processing capabilities, that depicts a plant’s status in real time. That makes it possible to test both the functionality and the runtime performance of automation concepts, and to optimize process workflows, before the real plants and machines are built and ready for use.

To meet the varying challenges in the planning process, Heitec uses a variety of tools for engineering, including the Vincent software environment from the IFF, the Fraunhofer Institute for Factory Operation and Automation. It works together with the CAD data for the plant layout to produce a virtual functional model automatically. In this way the machine’s automation can be developed, planned and commissioned in advance. If CAM data are available for products to be produced, or new products, the machines and plants can be prepared virtually, workflow controls can be adjusted appropriately, and the interplay of all components can be tested virtually, so that the machine operator on site can retool the equipment for new workpieces within a very short time.

Heitec’s HeiTPM solutions for IT integration make it possible to extend digitalization down to the shop floor level. In HeiTPM, offers a solution that downloads any desired data from the controls and sensors in the machines and systems on the shop floor, with high performance and free from interference. The tool supplements these with structuring and descriptive information for self-describing objects, and prepares them individually for analysis and visualization by various participants in the process. Since the current processing status can be viewed at any time directly in the ERP system, production managers can plan subsequent processes and retooling times more precisely. That cuts processing times and expenses, and makes handling easier. Real-time data from production make business planning more reliable and optimize material flows and resource allocation.

PR-Automatica-2018-Heitec-4.0-EN.zip